Does Your Auto A/C Hose Assembly Have Shut-Off Valves?

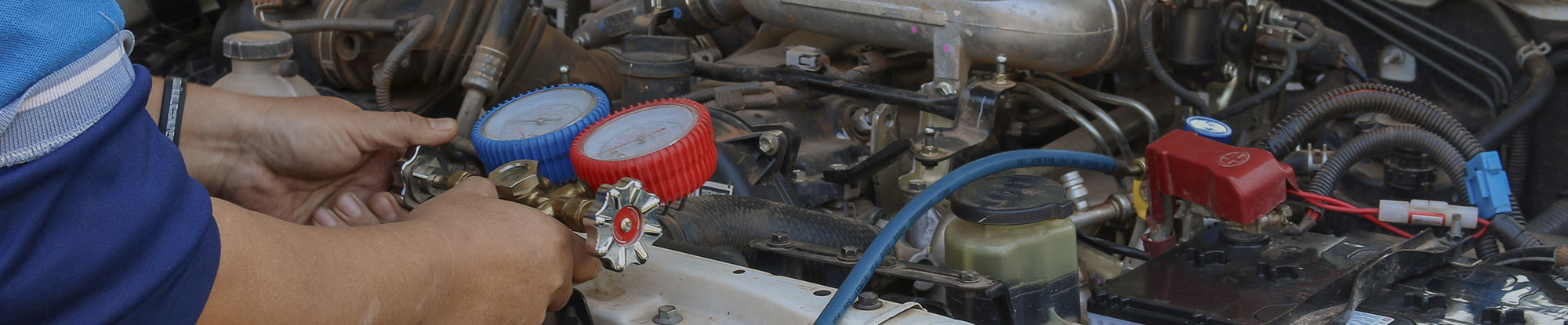

Every hose used in air conditioning service tools has to be equipped with shut-off valves. These valves may be automatic and manual, and the standards set by the SAE dictate that the valves should be positioned within twelve inches (thirty centimeters) from the automobile’s end of the hose, although some manufacturers have included these valves in quick couplers.

How These Valves Function

The valves are responsible for shutting down the refrigerant flow automatically whenever its hoses are removed. Fittings which are specific to certain refrigerants have to be connected permanently to the automobile end of the hoses used for servicing. Adapters for distinct systems, ports or refrigerants cannot be connected to the service hoses and then disconnected and replaced with an adapter which is designed for another refrigerant type.

This is why it is so important to get your A/C system serviced by a professional. They will perform the repairs the right way while ensuring every replacement part is premium in quality. Many car enthusiasts that attempt A/C repairs DIY overlook recycling and recovery which means the refrigerant is not properly reused and often released into the surrounding air where it contributes to pollution. Those who are determined to work on their own A/C systems should know as much as possible about the unit and engine cooling in general.

Dual And Single Hoses

When working with auto air conditioners or replacing them, you will learn that hoses come in two configurations, which are dual and single. The single hose uses the simplest design, which consists of the compressor which is used to power the system cooling while removing heat from surrounding spaces. Single hose systems will extract warm air from an area and then expel it outside (along with the moisture). This leads to air pressure which is negative since the air is continuously being forced outward, and as a result the cabin’s air needs replacing. Warm air seeps in through various openings, replacing that which is being removed. The problem with the single hose design is that the A/C typically has to operate harder to produce cooling, which leads to reduced efficiency compared to the dual hose.

Dual hose A/C systems make use of two exhaust hoses, one that acts as the air exhaust while the other will draw in air from outside. The air taken in through the vehicle’s cabin will be cooled within the system and then expelled back in. However, the cooling process produces heat within the A/C, and in order to cool it down, a second hose extracts air from outside which is then used for cooling down both the condenser and compressor coils.

The dual hose has many advantages over the single hose, the most important of which is the ability to cool down the vehicle’s cabin with greater efficiency while needing less work. As a consequence, dual hoses typically have a much longer lifespan than their single hosed counterparts, although dual hoses also carry a higher price tag.